Most furniture trends have a predictable lifecycle. Quite rarely, some designs are iconic enough to break through this pattern and redefine stylistic expression by establishing a new form. The epoxy resin river tables, which gained popularity and mainstream recognition around the early 2010s, have caught the artisanal industry by storm, creating a distinct category worthy of recognition. Manufactured from a particular type of resin, which blends seamlessly with imposing wooden slabs, the epoxy table design has become an idée fixe of dining furniture. In this article, we explore the evolution of the trend and account for the various materials and techniques that bring this iconic piece to life.

The origin of epoxy resin river tables

It is relatively safe to conclude that Epoxy and resin have been part of the furniture industry for several decades. Influencing woodworking techniques, these viscous materials have embellished a range of products. But it wasn’t before the introduction of this concept to the design of the river table, that furniture, and especially dining furniture, adopted a completely novel format.

While it is difficult to pinpoint the exact origin of the epoxy river table, it is easy to revisit its early adoption. Thanks to the ingenuity of Canadian woodworker Greg Klassen and his compelling artistic vision, epoxy tabletops have made a significant impact on the furniture design scene. Worthy of attention, they are now an inseparable part of luxury residential spaces and commercial dining areas.

The process of wood selection and preparation

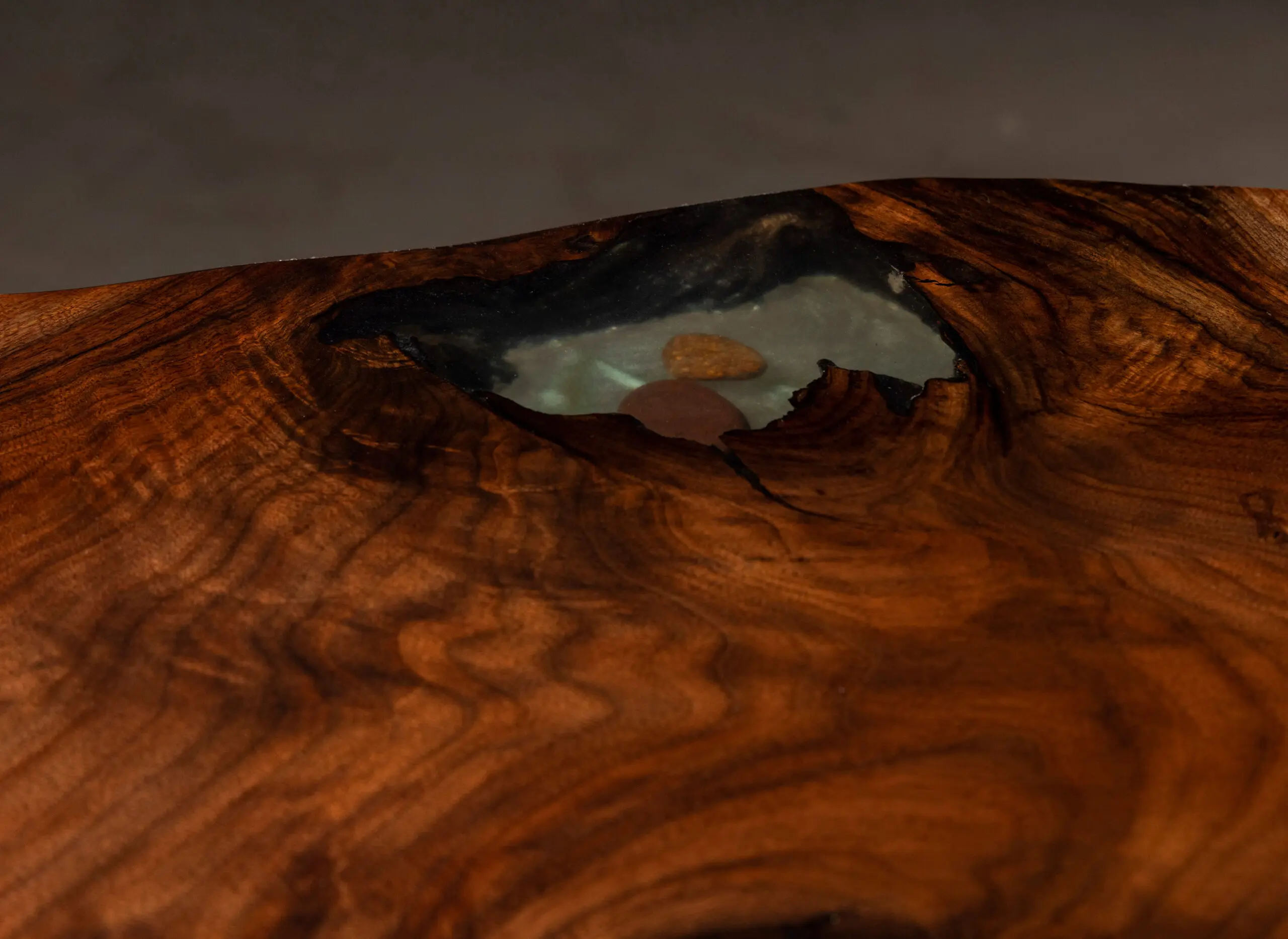

While some epoxy tables incorporate straight cuts, most of the visual gravitas is achieved through the selection of picturesque raw edges. Organically shaped, they represent the serpentine flow of the mountain river.

Inspired by nature and working in concert with its organic expression, we strive to find the best quality wooden slabs. This is done through a careful selection process and an endearing commitment to sustainable harvesting. Made from American black walnut and big-leaf maple, most tabletops exude rich colors and sophisticated textures.

SENTIENT uses premium wood slabs with low moisture content, environmentally acclimated through months of air-drying. These are carefully resurfaced and flattened to perfection before we begin the sanding process, much of which is done by hand. Designers often spend time looking at aerial images of rivers, to get inspiration for creating the corresponding curves, which are then carved by the craftsman. The tool of choice is often a dull chisel, with the occasional use of an angle grinder.

Applying the resin

Once a specific proportion of resin and hardener are mixed, craftsmen are vigilantly monitoring the exothermic reaction by maintaining an optimum working temperature. Designers can observe this process to suggest other pigments or chemical additives for further embellishment. These contribute to the aesthetic expression by infusing the viscous material with dimensionality and depth of color.

The epoxy pouring process requires additional deliberation. Some manufacturers seal the edges to prevent the epoxy from sipping through, while others avoid it in order to create a stronger bond. The debate on this is lively and ongoing. The strongest argument for using a sealant is the fact that raw wood naturally releases air, causing small bubbles to form throughout the epoxy. For manufacturers who are worried about the strength of the bond, it is important to mention that epoxy river tables can hold up to 1700 pounds without any compromise to the integrity of the surface. Put to an extreme test, the wood slab will buckle way before the bond between the materials.

As for the moldings, we create them from scratch, reflecting the unique design requirements of each project. Manufacturers make these from different materials, including melamine, high-density polyethylene sheets, Plexiglas, or acrylic. Some use silicone to further enhance the mold and avoid leaks, while others prefer fast dry caulk. In any case, it is best to add mold release, which is designed to be used with the resin. Then, once everything is in place, we apply the mixture slowly, using slight vibrations to prevent the formation of air bubbles.

Finally, the resin cures under controlled conditions, coalescing with the wood, to achieve a glass-like surface. The resulting furniture piece is a harmonious marriage between fine craftsmanship and aesthetic sophistication.

Variations on the original concept

With a spectacular adoption curve, epoxy resin river tables have inspired a plethora of creative variations. Together, these design concepts continue to push the frontiers of furniture manufacturing. One example is the reverse river table, where luxury furniture designers play with unique wooden slabs by encasing them with resin. The result is an imposing piece of furniture featuring a wooden island amidst a captivating river flow.

For those variations that strive to remain faithful to the original, the live edge dining table provides a great option to enhance the organic, flowing appearance of the river.

Given the transparent properties of the epoxy river design, manufacturers can embellish their bespoke models with additional artifacts like stones, shells, and other aesthetically appropriate items. These contribute to the unique quality of each model, personalizing the overall design to fit the particular commercial or residential space. The making of each table becomes a collaborative process, elevating its sentimental value. We have worked with many independent designers, turning epoxy resin into a creative canvas for their artistic expression. Clients love the process, as it leaves them with a unique masterpiece.

Finishing options for theepoxy resin river table

While no two projects are alike, designers usually prefer to avoid sealants, which can dramatically change the natural color and texture of the slab. Instead, subsequent polishing imbues each tabletop with a lustrous sheen, all the while preserving its raw, organic appearance. With several layers of protective finish, which is repeatedly sprayed and sanded, the artisan safeguards the visage and greatly enhances its durability. The resulting piece is a smooth canvas that is ready to entertain.

We use natural oils like Tung or Danish that can be applied directly to the epoxy. They are known for penetrating the wood fibers, providing additional protection, and accentuating the grain. We also use varnish, which comes in its water-based or oil-based form and provides durable protection through the creation of a stronger film. Designers employ this finish for various color manipulation options including matte, gloss, or semi-gloss that enhance the natural look of the slab.

Other polishing agents can be applied as well, bestowing an ethereal glow with durable protection. These include polyurethane and epoxy topcoat, or wax, which is usually added as a final touch after prior applications of varnish and oil.

Maintenance considerations –

how to take care of an epoxy table?

The epoxy tabletop is a resplendent piece of art. With proper care and maintenance, it can remain an interior focal point for years and possibly decades to come.

The first consideration is to avoid direct exposure to sunlight, as UV rays can cause slight discoloration over time. Other than that, dust, spills, and most mild stains are wiped away with a soft cloth, using a gentle and repetitive motion. When necessary, we recommend a mild soap or a selection of specialized epoxy cleaners, followed by a thorough rinse. The surface must be dried with a soft fabric immediately afterward.

We always advise owners to be proactive through regular inspections to identify signs of wear. Many times, the finish gets compromised with scratches and dulled areas, but light sanding and reapplication of the finishing coat can restore most of the original sheen.

Owning an epoxy resin river table

SENTIENT has created many models centered on the epoxy river design. Located in Brooklyn, we follow the New York design scene very closely, to create unique statement pieces that redefine dining furniture. Undoubtedly, this imposing centerpiece is the pinnacle of upscale interiors, elevating the space it inhabits. Drawing its inspiration from nature and born through a laborious and artful woodworking process, the epoxy river is the most elegant addition to the modern dining area.

Our epoxy table collection is a testament to fine craftsmanship and nascent design, with infinite customization options. Unveiled through a bold aesthetic vision and years of expertise, each piece represents a unique statement and a pinnacle of upscale furniture.